| Availability: | |

|---|---|

| Quantity: | |

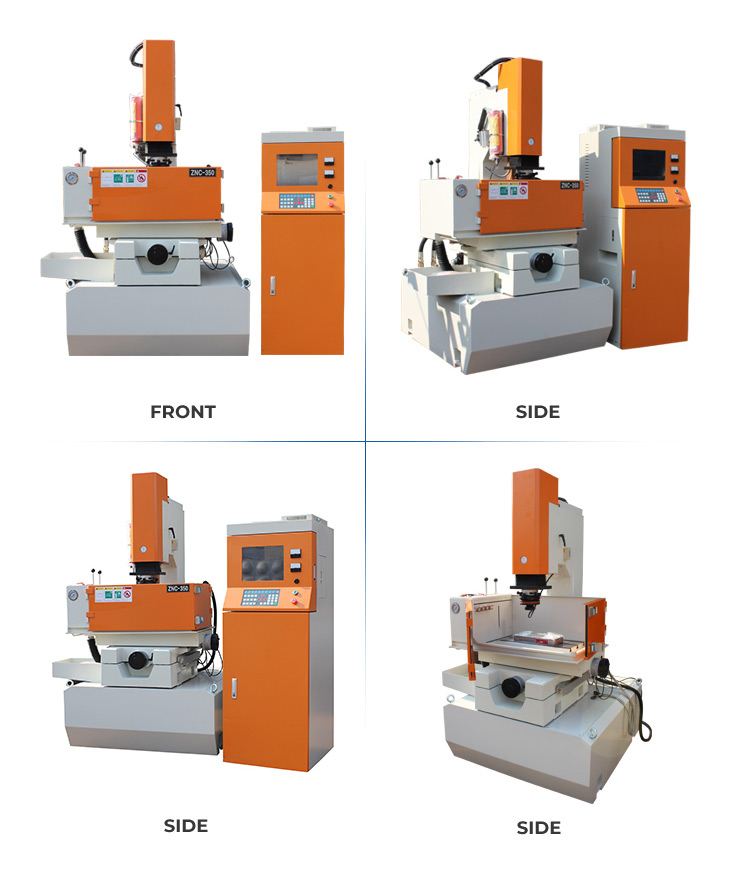

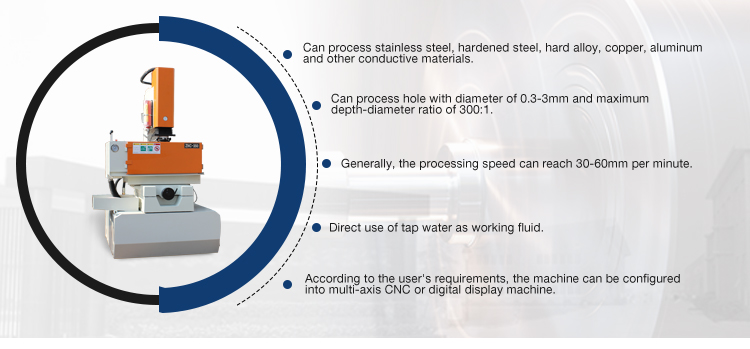

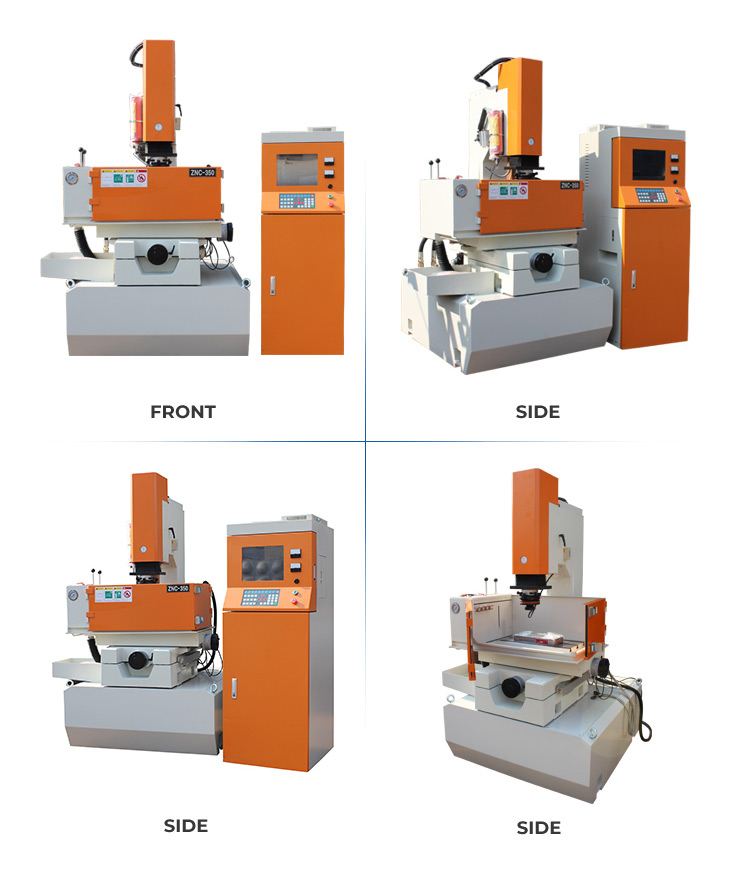

ZNC350 Die sinking EDM Characteristic:

High rigidity mechanical structure and humanized design have excellent cost performance;

Various functions such as deep holes, large areas, and super hard materials to meet various

mold processing requirements;

Ten segments of programmable processing, from coarse to fine, completed at one time

convenient and flexible;

Simple operation interface, suitable for all levels of personnel, easy to master;

The unique two-stage can set the servo system to greatly increase the processing speed;

Computer built-in expert system can minimize electrode loss;

UItra-fine processing surface, and equipped with mirror surface processing circuit;

High-sensitivity anti-carbon deposition circuit ensures that no arcing occurs;

Multiple fire safety protection devices to ensure safe and reliable use;

Modular electrical design, extremely low failure rate, easy to upgrade.

Parameter Table:

| Model number | ZNC 350 |

| Workbench size(mm) | 600*300 |

| Working slot size(mm) | 820*500*300 |

| X-Y-Z travel(mm) | 300*200*200 |

| Spindle head stroke(mm) | 200 |

| Electrode lifting weight(kg) | 60 |

| Max. workpiece weight(kg) | 500 |

| Electrode plate to table distance(mm) | 150-550 |

| Working fluid capacity(L) | 280 |

| Dimension(mm) | 1320*1220*2240 |

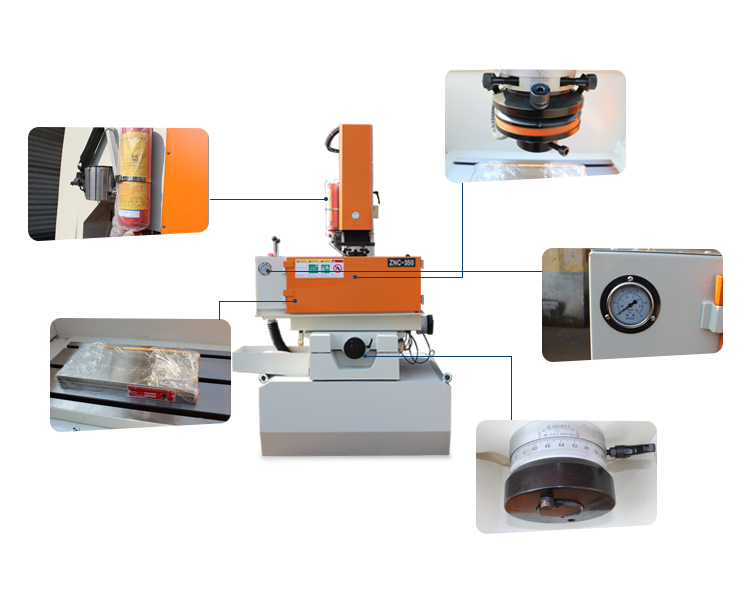

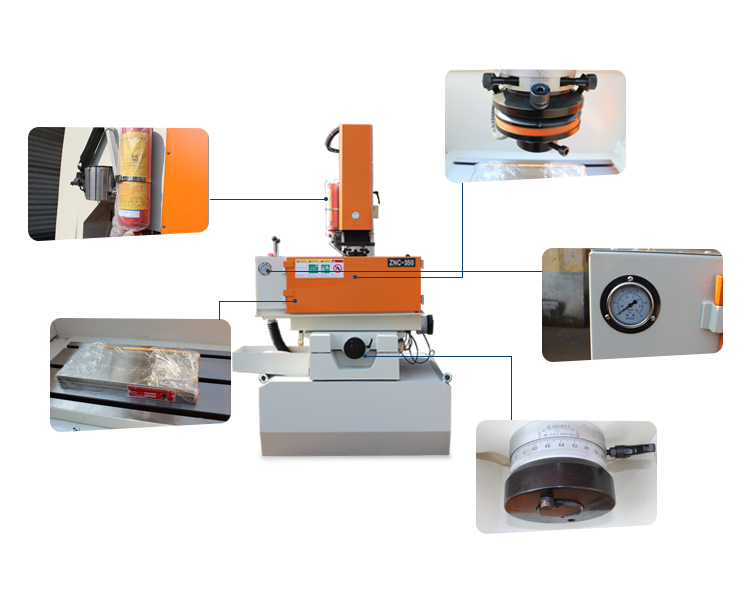

Standard accessories:

Oil strainer, standard electrode head magnetic injector, drill chuck, fixture set, tool box, quartz work light

Optional accessories:

Automatic fire extinguisher, processing fluid cooler, magnetic seat, 3R fixture

* "F in the table model indicates that the control cabinet is a screen display control cabinet. In the distribution box model,"A is a single-axis digital tube type and" is a single-axis screen display type

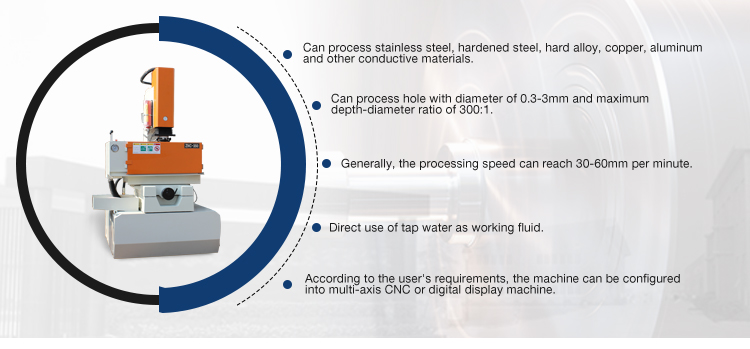

ZNC350 Die sinking EDM Characteristic:

High rigidity mechanical structure and humanized design have excellent cost performance;

Various functions such as deep holes, large areas, and super hard materials to meet various

mold processing requirements;

Ten segments of programmable processing, from coarse to fine, completed at one time

convenient and flexible;

Simple operation interface, suitable for all levels of personnel, easy to master;

The unique two-stage can set the servo system to greatly increase the processing speed;

Computer built-in expert system can minimize electrode loss;

UItra-fine processing surface, and equipped with mirror surface processing circuit;

High-sensitivity anti-carbon deposition circuit ensures that no arcing occurs;

Multiple fire safety protection devices to ensure safe and reliable use;

Modular electrical design, extremely low failure rate, easy to upgrade.

Parameter Table:

| Model number | ZNC 350 |

| Workbench size(mm) | 600*300 |

| Working slot size(mm) | 820*500*300 |

| X-Y-Z travel(mm) | 300*200*200 |

| Spindle head stroke(mm) | 200 |

| Electrode lifting weight(kg) | 60 |

| Max. workpiece weight(kg) | 500 |

| Electrode plate to table distance(mm) | 150-550 |

| Working fluid capacity(L) | 280 |

| Dimension(mm) | 1320*1220*2240 |

Standard accessories:

Oil strainer, standard electrode head magnetic injector, drill chuck, fixture set, tool box, quartz work light

Optional accessories:

Automatic fire extinguisher, processing fluid cooler, magnetic seat, 3R fixture

* "F in the table model indicates that the control cabinet is a screen display control cabinet. In the distribution box model,"A is a single-axis digital tube type and" is a single-axis screen display type